Focus on wind farm construction: three typical cable challenges

TL;DR

- Grid expansion is crucial for the energy transition and energy security.

- By 2024: 3,085 km of new power lines; by 2030: another 12,000 km planned.

- Underground cables are preferred for environmental and public acceptance reasons.

- Challenges: bureaucracy, opposition, and labor shortages.

- Solutions: public involvement, smart technologies, and innovative cables.

Goal: Climate neutrality and sustainable energy supply by 2045. 🌍

Building an onshore wind farm is a technical masterpiece – and cable installation plays a crucial role. Between wind turbines, transformers and grid connection points run hundreds of meters of medium-voltage cables that transfer the generated energy safely and efficiently to the grid. But it’s exactly these wind farm cables that often become the most critical bottleneck in the entire project.

Wind power cabling is far more than just sourcing materials. It requires precise planning, coordination and experience – from choosing the right cable type to ensuring timely delivery to the construction site. Even small delays or changes in plans can significantly affect progress and trigger high additional costs.

Add to this the logistical challenges: large cable drums, different conductor cross sections, special packaging, and ever-changing construction site conditions. Without forward planning, you risk bottlenecks – and that can delay the entire grid connection of the wind farm.

In this article, we look at the** 3 biggest challenges in wind farm construction** – and show how proactive logistics and the right cable strategy can help you stay on schedule and maximize efficiency.

Find out why onshore wind farms are a crucial pillar of the energy transition here:

Onshore-Windenergie als Pfeiler der Energiewende | EnBW

Viele Faktoren haben den Bau von Windenergieanlagen in den letzten Jahren gebremst. Lesen Sie hier die Gründe!

Wind farm construction site

Challenge 1: Tight construction timelines and fixed deadlines

In wind farm construction, schedules are rarely flexible. Any delay in cable laying directly impacts the entire build process – from foundation and tower installation to commissioning. Since grid connection deadlines are usually contractually binding, a missing medium-voltage cable can quickly lead to costly site downtime.

Typical causes of delays:

- delayed cable deliveries or unclear scheduling

- inaccurate material planning in large-scale projects

- weather conditions delaying underground cable installation

- lack of coordination between suppliers, civil engineers and installers

Especially for wind farm projects involving several kilometers of NA2XS(F)2Y, precise delivery coordination is essential. Partial and complete deliveries must be scheduled to match the actual construction progress.

Efficient Logistics Solutions

With precise cable capacity planning and responsive logistics, even high-pressure timelines can be handled efficiently. This ensures the wind farm’s grid connection stays on schedule – and energy flows reliably.

Want to know which cable types are used in wind farms? Check out this article:

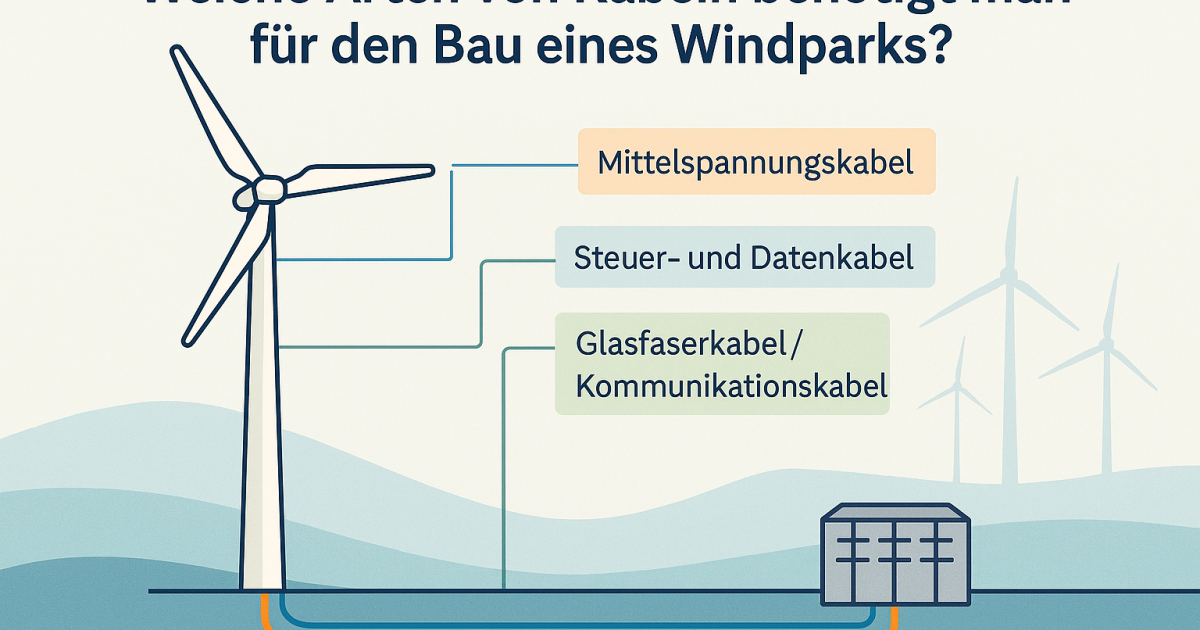

Welche Arten von Kabeln benötigt man für den Bau eines Windparks?

Die Verkabelung ist ein zentrales Element jeder Windkraftanlage und beeinflusst maßgeblich die Effizienz, Sicherheit und Wirtschaftlichkeit eines Windparks.…

Challenge 2: Large delivery volumes and specialized packaging

A modern onshore wind farm requires several kilometers of medium-voltage cables – often of the type NA2XS(F)2Y, N2XSY or NAYY. These cables weigh several tons per drum and require smart logistics to avoid damage, confusion and costly delays.

The bigger the project, the more complex the material coordination becomes:

- Different cable cross-sections and conductor types must be clearly assigned.

- Drum sizes and installation units vary by cable length and location.

- Clear markings and packaging systems on-site are key to avoid installation mistakes.

Our experience shows: Planning for storage and packaging units in advance not only saves time but also reduces the risk of material loss and reorders.

Typical Requirements and Solutions

A clear cable logistics strategy is the key to avoiding material shortages and costly downtime. This helps maintain control – even for projects involving dozens of kilometers of wind farm cabling.

Anyone who integrates packaging, storage and labeling early into the planning process ensures that the wind farm cables arrive exactly where they’re needed – with no time lost and no disruption to the construction flow.

NA2XSF2Y Cable

Challenge 3: Last-minute project changes

Hardly any wind farm project goes exactly to plan. Construction site conditions, supply bottlenecks, or new requirements from the grid operator often lead to spontaneous adjustments – and this is where the true flexibility of cable logistics is revealed.

Typical scenarios:

- A cable route has to be changed due to geological conditions.

- Cable types or conductor cross-sections change after a new grid calculation.

- The delivery location changes at short notice because sections progress faster or slower than expected.

In such cases, it’s crucial that the supplier has its own stock and a quick response time. Only then can changes to cable lengths or additional earthing components be provided promptly, without delaying the project.

An experienced partner can make all the difference:

- Rapid re-delivery from central stock within Germany

- Flexible redirection of deliveries in case of planning changes

- Close coordination with project managers, civil engineers and installation teams

- Documented traceability to keep all changes transparent

Short-term changes aren’t the exception – they’re part of everyday life in wind farm construction. What matters is being prepared. A well-designed supply chain, clear communication, and agile warehousing structures ensure the project stays on schedule – and the wind farm connects to the grid on time.

Avoid delays or issues during your wind power project by understanding early on why NABU may file objections to certain sites:

Wann klagt der NABU gegen Windkraftprojekte?

45 Klagen wurden wegen Fehlplanungen bei Windenergie zwischen 2010 und 2019 vom NABU auf den Weg gebracht. Nicht weil der Windenergieausbau aufgehalten werden soll, sondern weil immer wieder Vorhaben und Planungen eklatant gegen Naturschutzrecht verstoßen.

Quality and sustainability as success factors

In addition to time and logistics, cable quality plays a decisive role in the long-term performance of a wind farm. After all, the installed medium-voltage and high-voltage cables are expected to transmit energy reliably for decades – even under extreme weather and changing load conditions.

A high-quality cable system for wind power stands out due to several factors:

- Material quality: XLPE-insulated cables like NA2XS(F)2Y or N2XS(F)2Y provide high dielectric strength and excellent long-term protection.

- Standards compliance (PDF): All components used should meet key standards(PDF) such as DIN VDE 0276, VDE 0298, or IEC 60502.

- Ease of installation: Cable design must allow for efficient and safe installation – even under difficult ground conditions.

- Environmental aspects: Recyclable materials and the reuse of drums or conductor materials help reduce ecological footprint.

More and more project developers are placing value on sustainable cable systems that combine energy efficiency with durability. This applies not only to the material selection, but also to supply chains: short transport routes, local storage near the project, and optimized packaging concepts reduce emissions and logistics effort.

The combination of technical quality, ecological responsibility, and efficient logistics makes modern wind farm cabling a central success factor for grid expansion. Anyone who invests in smart solutions here builds the foundation for stable and sustainable energy flow – now and in the future.

Wind farm landscape

Conclusion: Successfully connected to the grid

Cabling is the backbone of any wind farm – and at the same time one of the most sensitive parts of the project. Tight schedules, complex logistics and last-minute changes aren’t the exception, they’re the norm. Those who identify and address these challenges early avoid standstills, cost overruns and missed deadlines.

Successful wind farm cable projects rely on three core principles:

- Structured planning – clear workflows, coordinated delivery schedules and defined responsibilities.

- Flexibility – in-house stock and short response times when changes occur.

- Quality – durable, standards-compliant cable systems and sustainable logistics processes.

With the right mix of experience, organization and technical know-how, even complex wind farm cabling can be implemented efficiently. This keeps construction on track – and ensures the wind farm delivers power exactly when it’s needed.

KLZ – your partner for successful wind farm cabling

Whether you need medium voltage, underground cables, or complete grid connection solutions – we don’t just provide the right materials, but the kind of experience that actually moves your project forward. For years, we’ve been supporting wind power projects throughout Germany and the Netherlands – from technical consulting and material selection to on-time delivery.

Our advantage? Real-world experience: We know how tight construction timelines in wind projects are, which cable systems have proven themselves, and what really matters in logistics. Thanks to our central storage facilities in Germany, we respond quickly to changes and keep supply chains stable – even when your project gets dynamic.

With our network, market knowledge, and passion for renewable energy, we ensure your wind power project connects to the grid on time – and without the drama.

➡️ Planning a new wind farm or need help choosing the right cables? Then talk to us – we deliver the cables, solutions, and expertise that make your project a success.

Ready for theEnergy Transition?

From wind and solar park planning to delivering high-quality energy cables, we bring your projects to life.

Free initial consultation for your project.